The uncertain nature of the customer demand need to take into consideration by generating the production plan and in particular the production quantities, to meet uncertain customer demand in the best way possible and maximize the profit, by minimizing production costs. Aggregate planning is a process by which a company decides about their ideal levels of capacity, production, inventory, stock-out situations, pricing, subcontracting, etc. Production planning, is the correct placement of production orders concerning place, or region, of production, and time scheduling and sequencing of production orders. The parameters are usually production rate, workforce, overtime, machine capacity level, subcontracting, backlog, and inventory on hand. The amount of overtime production planned is a parameter for aggregate production planning. Production planning for fashion apparel products has to cope with demand uncertainties. Collaborative forecasts created by various enterprises are an important input in aggregate supply chain planning. However, at the time of generating the production plan, the predicted customer demands are largely uncertain.

Search Results for: supply chain planning

How Does the International ship and Port Facility Security Code Enhance Supply Chain Security?

Each ship must develop a unique plan to protect against security threats. The plan must be approved by the ship’s flag state. Port facilities must also develop a security plan to protect port infrastructure. The plan outlines the responsibilities of port facility personnel and how to respond to potential security breaches. The ISPS Code introduces a three-tiered system of security levels: Level 1: Normal security measures, Level 2: Additional security measures due to an elevated threat level, and Level 3: The highest level of security measures is activated in response to a specific threat or a known risk. Each ship and port facility must appoint a Ship Security Officer (SSO) to maintain the security plan and coordinate actions with relevant authorities. Regular training and drills are mandated for both ship and port personnel to ensure personnel are well-prepared for potential security incidents. The code sets guidelines for information sharing and cooperation between all parties to enhance maritime security. The ISPS Code has significantly improved supply chain security, particularly in the global maritime industry. It reduces the risk of terrorist attacks and piracy, enhancing the security of ports that transport goods across international borders. It encourages risk mitigation and threat assessment, enhancing the security of cargo and fostering international cooperation. It improves monitoring and surveillance, requiring port facilities to implement surveillance systems and ships to be equipped with tracking systems. It requires both ships and port facilities to have contingency plans in place in the event of a security breach or a threat. It provides guidelines for the protection of critical infrastructure against physical attacks or other types of sabotage. The ISPS Code instills confidence in global trade and by ensuring consistent security maintenance using International ship and Port Facility Security Code.

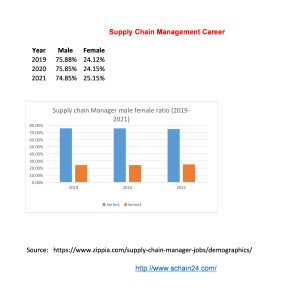

What is a Supply Chain Management Job and Career?

In a case study, based on US-based companies, first-level management is of about 0-4 years. To understand the supply chain management job and career we can remind ourselves about the example of leaf cutter ants. APICS, founded in 1957 as American Production and Inventory Control Society and re-branded as The Association for Supply Chain Management in 2018, launched their CSCP (Certified Supply Chain Professional) programme in 2006. Institute for Supply Management, founded in 1915 as the National Association of Purchasing Agents, launched its CPSM Certified Professional in Supply Management programme in 2008. Council of Supply Chain Management Professionals, founded in 1963 as the Council of Logistics Management, launched their SCPro programme in 2011.For Supply Chain Management roles, “Process Engineer”, and “Supply Chain Analyst”. For Supply Chain Systems Manager roles, “Supply Chain Manager”, Vice President, Supply Chain Management”. For Sales and Customer Service roles, “Account Specialist”/ “Customer Service”, “Customer Service Manager”, “Account Manager/Supply Chain Sales” etc.

What is the Role of Inventory in Supply Chain Management?

In Supply Chain Management (SCM), efficient inventory management is the result of a combination of interdependent procedures that work together to promote robustness and efficiency. Making wise decisions is necessary for inventory optimization in order to preserve equilibrium, reduce carrying costs, and avoid stockouts. Warehouse management uses sophisticated warehouse management systems and tools like SAP MM to guarantee effective product storage, retrieval, and dispatch. Shipping administration, which integrates technologies for route optimization, real-time tracking, and effective returns management, is essential for the efficient, dependable, and quick delivery of goods. Understanding and projecting customer demand is a key component of demand planning and forecasting. Our future product demand predicted by combining historical sales data, market intelligence, forecasts for raw materials, and predictive analytics. By proactively adjusting production schedules, procurement tactics, and supply plans, businesses can avoid stock-outs and guarantee that capital is not tied up.

What Makes Toyota’s Supply Chain Management a Benchmark for Excellence?

Toyota has an effective supply chain strategy that puts value and efficiency first. It has adopted the Just-In-Time (JIT) system, which guarantees on-demand delivery of materials and components while cutting waste and inventory expenses. By employing a tiered supplier system and incorporating employees at all levels in cooperative improvement initiatives, Toyota also cultivates long-term relationships with its suppliers. The Toyota Production System (TPS) maximizes efficiency while reducing waste and overproduction. To match production schedules with market demand, the organization employs sophisticated demand forecasting systems. Toyota also uses buffer stockpiles for essential components and dual-sourcing tactics to proactively manage supply chain risks. For improved supply chain monitoring and predictive analytics, the business incorporates cutting-edge digital technologies like IoT and AI.

The post Covid-19 Supply Chains: A Brief Discussion |

The U.S.-China trade war and the Covid-19 crisis have prompted manufacturers worldwide to reassess their supply chains, focusing on increasing domestic production, boosting employment in their home countries, reducing dependence on risky sources, and rethinking lean inventories and just-in-time replenishment strategies. The pandemic has exposed vulnerabilities in production strategies and supply chains, leading to increased political and competitive pressures. Modern products often require specialized technological skills, and manufacturers often rely on suppliers and subcontractors who focus on specific areas. However, relying on a single supplier deep in their network increases disruption risks. To mitigate these risks, manufacturers should categorize suppliers as low-, medium-, or high-risk, using metrics like revenue impact, factory recovery time, and alternate sources.

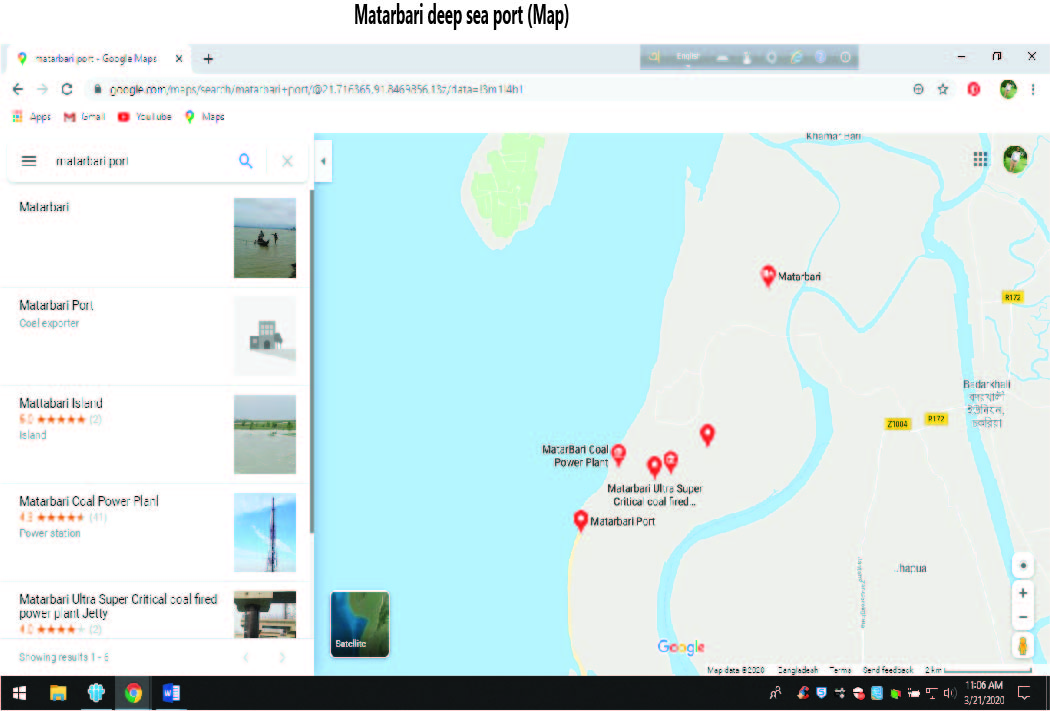

About the Matarbari deep sea port: A Supply Chain Management perspective |

To ensure load unload of deep draft vessels the Matarbari port is essential for Bangladesh and adjacent countries and areas. The Matarbari deep sea port has a 16m depth that will help 16m draft vessels to unload their cargo at the terminal. At deep sea, currently mother vessels unload the cargo at feeder vessel and they carry the cargo to the Chittagong port. The present seaports (Chattogram sea port and Mongla sea port) of the country do not have the capacity to handle huge containers and vessels and the building of a deep sea port is the only solution. Chittagong port can’t load unload from more than 9.5 meter vessels.